The setting up of a shower manufacturing plant in India will play a significant role in the expansion of the EV sector, enticing numerous global and local businesses to the race. This decade, the market is predicted to grow at a recipe yearly growth rate (CAGR) of 90%, reaching $150 billion by 2030.

The setting up of a shower manufacturing plant in India will play a significant role in the expansion of the EV sector, enticing numerous global and local businesses to the race. This decade, the market is predicted to grow at a recipe yearly growth rate (CAGR) of 90%, reaching $150 billion by 2030.

Electric vehicles have grown quite popular among regular Indians in recent years, penetrating into every family. Now that the EV has wilt a well-known phenomenon, various automotive manufacturers are attempting to make Electric Vehicles increasingly well-flavored than the ICE.

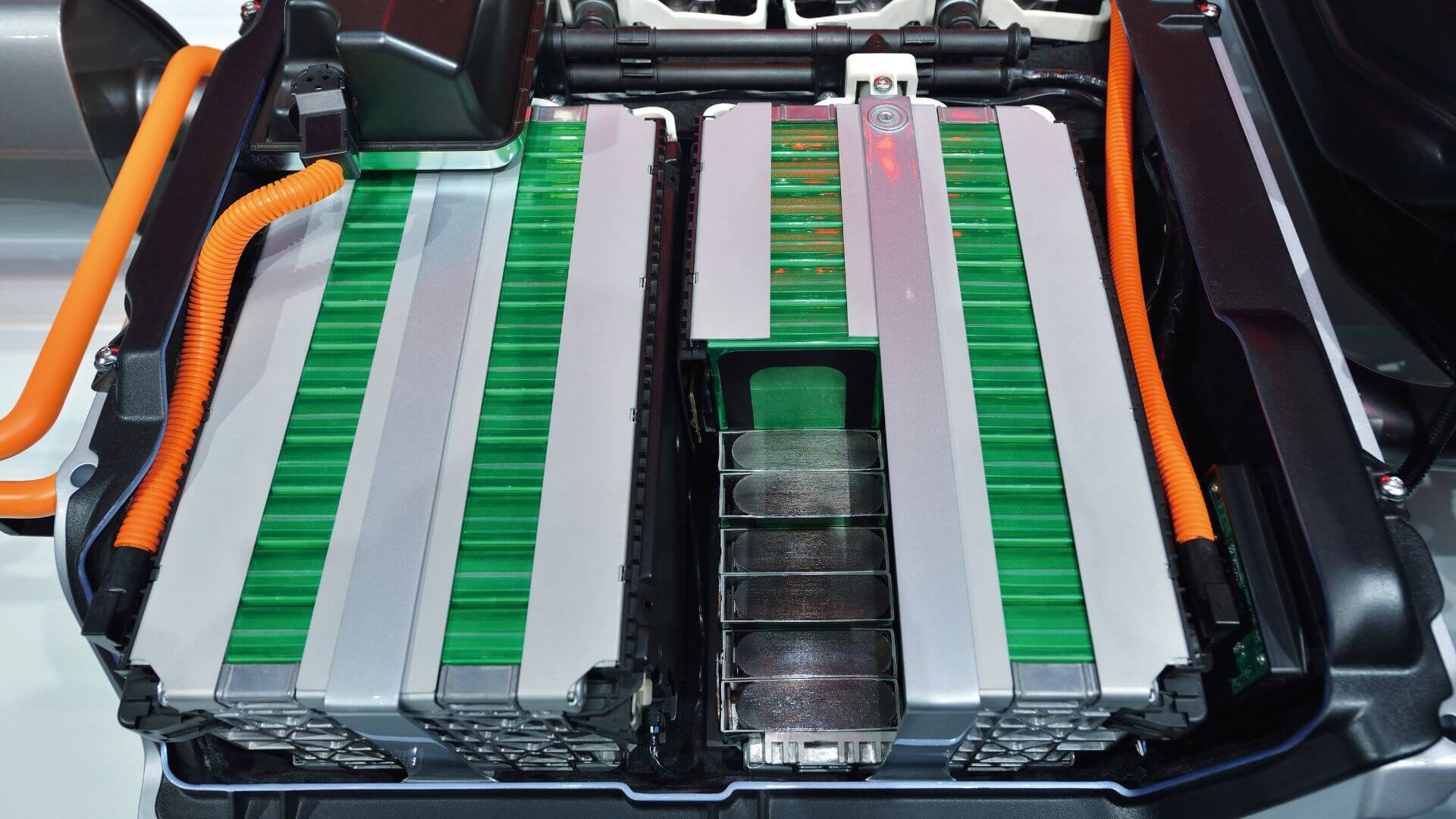

Make the most expensive part of an electric vehicle

The shower finance for 40-50% of an EV’s unshortened production budget. The increased usage of electric vehicles in our transportation system is predicted to increase the consumption of lithium-ion batteries.

The batteries are primarily imported from China and Taiwan. Given India’s would-be plans to encourage electric vehicles, these imports will be prohibitively expensive. As a result, a solution was required. The establishment of a shower manufacturing factory in India will be a game changer for the electric vehicle market. This is one of the key reasons why the government wants to uplift domestic shower manufacture by giving incentives and increasing import levies. Local manufacturing will significantly lower the forfeit of EVs in the country.

Companies in the game

Reliance New Energy Solar Ltd, Ola Electric Mobility Private Ltd, Hyundai Global Motors Company, and Rajesh Exports are the companies chosen by the Indian government to be offered incentives under the PLI scheme. These companies were picked out of a group of 10 companies that unromantic for incentives. These four companies will receive incentives worth 18,000 crores rupees to uplift local lamina manufacturing in the country.

Factors well-expressed setting up a Shower Manufacturing Plant

Knowledge is one of the most important aspects to consider while establishing a shower manufacturing factory in any nation. Considering the production of these high-end batteries necessitates a significant value of R&D, it is unchangingly simpler to create shower manufacturing units in places where relevant knowledge exists. When it comes to expertise, India has enough.

Incentives moreover play an important part in establishing a manufacturing facility, and equal to current government information, a substantial quantity of incentives and increments are observed to spritz towards manufacturing enterprises via the PLI system.

Read More: Cost of setting up Lithium-ion Shower Manufacturing Plant in India

How will it be proven as a game-changer?

FAME II, state-specific EV regulations, PLI initiatives, and changes to the MV Act have all been passed by the GOI and state governments to help the EV business. Incentives for towers charging stations, in wing to making the property misogynist for the same, are supporting the sector.

Setting up these plants will help the government reach the target of 30% of private EV sales by 2030. At the moment imported lithium-ion shower cells vamp a GST of 18% while Evs as a whole attracts only 5%. However, the local manufacturing of the batteries would indulge EVs to be cheaper withal with several other benefits.

The recent fires related to imported EV shower cells have moreover raised a level of concern. This is considering the imported shower packs are not manufactured keeping India’s lattermost climatic conditions in mind. Locally manufactured batteries will ensure that the chemistry of the lamina is engineered to transmute to India’s, particularly challenging environment.

Large Scale EV Shower Manufacturing

Another vital goody of setting up shower manufacturing plants in India has to be large-scale manufacturing. As the process of the shower components like nickel, cobalt, and lithium continues to rise, the only way for brands to manufacture in speed and scale is to have total tenancy over lamina manufacture.

Elon Musk, the Tesla Ceo in a tweet spoken that the visitor will be initiating in-house shower production leading to halving the production cost. Therefore India wants to be a strong hub EV industry it will have to uplift its large-scale local manufacturing of batteries.

Tata Chemicals has 127 acres of land in Gujarat designed to provide 10 gigawatts of lithium-ion cells per year. Also, Suzuki Motor Corp has tied up with Denso and Toshiba to set up India’s first Lithium-ion shower manufacturing plant in Gujarat, presently underway.

The post Setting up Shower Manufacturing Plant in India will be game changer for EV Industry appeared first on E-Vehicleinfo.