“I am testing these motor flying Inverters on this motor flying plane”

Motors, inverters, and power systems for electric watercraft have strict requirements for weight, efficiency, and safety. For this reason, these motors are pushing technology, going to higher voltages, upper phase counts, and unique topologies for both the motors and inverters. Many of these decisions have electrical and mechanical effects that stupefy the unshortened aircraft. These evolutions in motor technology require significant amounts of testing from prototype to installation, and ultimately certification. A significant value of this testing is not only on the components but involves testing the unshortened watercraft electrical network for system stability and certification.

In this webinar at the Fall Virtual Priming on EV Engineering, presented by HBK, we will review new tests for evaluating these motors and power systems:

- Copper bird testing & flight cycles

- High phase count evaluation

- Failure testing

- High fundamental testing

- Electromechanical evaluation

- Structural effects of electric motors

- High voltage measurements

Other sessions at our Fall Virtual Priming include:

Managing Heat Through E-Fluids

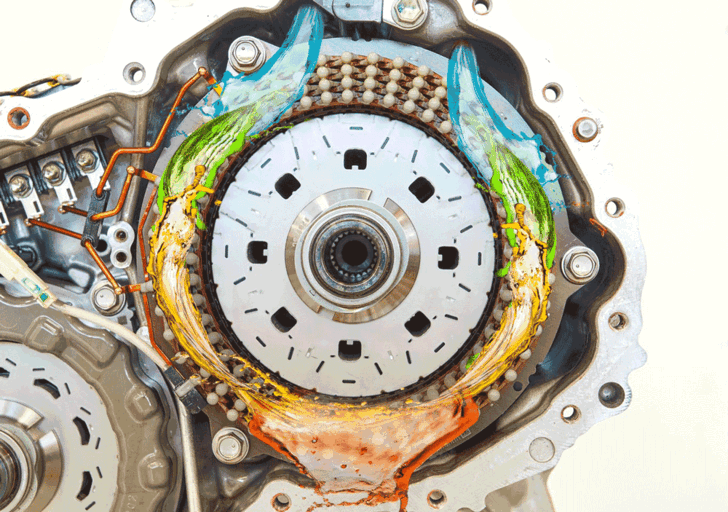

New thermal management driveline e-fluids, designed to enable the latest electrified powertrains and batteries to perform at their very best, have been ripened for the latest electric vehicle hardware.

For example, many older electric vehicle powertrains were ripened using will-less transmission fluids (ATF). Not optimised for EVs or their thermal management, these are stuff superseded by the latest generation of lubricant fluid technology, termed driveline “e-fluids”. e-Fluids are optimized for automotive electrified hardware types, such as the latest generation of e-axles, and tomfool and protect such devices much increasingly effectively.

Lubricants are now expected to be in uncontrived contact with powered motor windings and exposed and electrically insulated electrical components. Characteristics such as the worthiness to tomfool electrically energized surfaces in wing to other surfaces that can wilt hot as well as the protection of exposed electrics are of increased importance.

Motor efficiency increases with reduced fluid churning losses and suitable cooling. It can be remoter improved using optimised fluids which provide thermal management. Ensuring suitable wear performance as required by the hardware engineers is of vital importance to protect the gears and bearings, and is an essential goody provided by the e-fluids.

The latest types of ingredient components used in e-fluids have evolved significantly over traditional types, and a new matriculation will be described in the webinar. This is the most recent type of powertrain e-fluid technology to enter the market, which has no corrosive zippy sulfur ingredient present, sometimes termed “sulfur-free”.

The e-fluid is an engineered component and forms part of the overall diamond of the electrified hardware. The presentation will imbricate the fundamentals of the latest e-fluid design, fluid properties, and how a thermal management e-fluid is weightier evaluated for performance.

This presentation will be of interest to engineers and fluid formulators seeking an introduction the vital principles overdue fluid thermal design. In addition, the latest fluid testing methods to write some of the hardware challenges, resolved by the fluid, will be described with the aim of enabling the engineer to make the weightier thermal management fluid nomination for their latest hardware designs.

See the full session list for the Fall Virtual Priming on EV Engineering here.

Broadcast live on October 2 – 5, 2023, the priming content will span the EV engineering supply uniting and ecosystem, including motor and power electronics diamond and manufacturing, lamina development, shower systems, testing, powertrains, thermal management, spin protection, wire and cable, EMI/EMC and more.